Finally made some free time a few weeks ago so I could assemble the tracks and get them installed onto the carrier. Everything went pretty smoothly and the process was much easier and quicker than I thought it would be. The following shots are some I took that day but its taken me this long to get them uploaded for MLU...

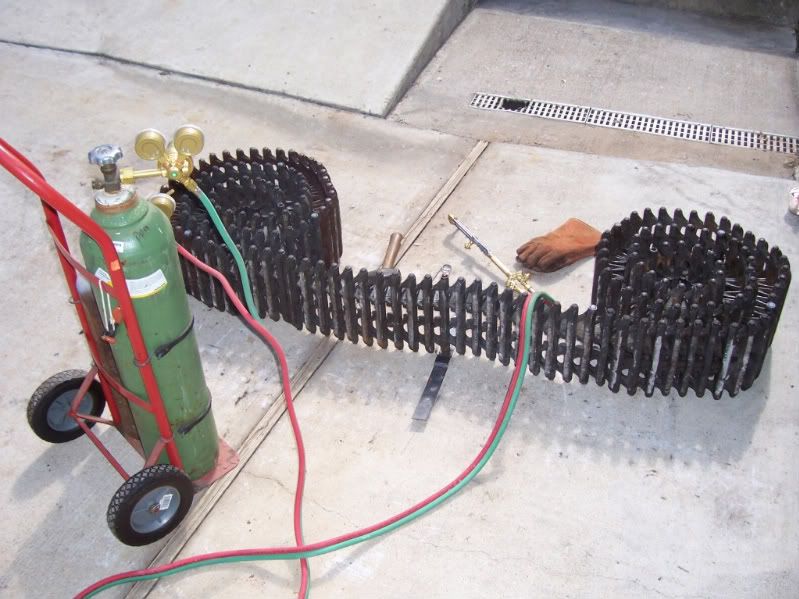

I had a handful of pins which were designed to be welded and knew they would be no good for emergency repairs in the field so used them to make up for my shortage of pins that can be removed which will stay in my recovery kit on the carrier. I opted to heat one end with my torch and then was able to make mushroom caps with a small hammer so they look similar to original factory pins.

The next step was to carefully roll each of the complete tracks between my jeep and the carrier so they would be in front of the vehicle. Fortunately I had no problems but hindsight says I should have moved the jeep to avoid a potential accident.

Both tracks now in place, only to realize I had rolled one backwards when compared to the other so I had to move it across the garage again after pulling the carrier out onto the driveway. Everyone needs to practice moving sets of tracks by themselves to get proficient at it.

Tracks starting to get into position

Tracks all laid out

Having a driveway that goes up hill, I used my truck to pull the carrier out of the garage and then let it roll onto the tracks after I had laid them out.

After having warmed up by moved the tracks around several times, dragging them onto the vehicle over the wheels was a piece of cake.

I used a modern turn-buckle type track jack to get everything tightened up for installation of the final pin on each side. Seemed pretty easy and overall both tracks took about an 2.5 hours to assemble, position and completely install to where I could drive back into the garage. Assembly with the torch probably took more than half of the total time since I didn't have everything in place to start working.

The final thing I did was to put the vehicle up on jack stands again so I could test run the tracks in the garage. I'd done this originally for testing the differential, engine and transmission together so thought it would help ensure I had no problems with the tracks when I actually took it down the road. After about an hour of running and shaking rust dust free, I broke each track and removed a single link. Being in the air, breaking the track, removing a link and reassembling the track only took six minutes per side. After another hour of running, I decided to go ahead and pull a second link from each side which made the track fairly tight but still within the specifications in the vehicle manuals. This way I still have the full range of idle wheel adjustment when I start driving and things continue to wear in.