Hi Tony

Your graph came out giving more information than mine because of the way you ordered the data to be graphed. Did you have to type all this data back in because or did you capture from the picture? (Will add a photo of location of measurements)

Well this afternoon, did flush the radiator with radiator cleaner, because of the right angle filler neck you can not see in to see if it really cleaned. But what came out was nearly clear. The engine had been hot tanked when it was rebuilt so it was clean inside.

As to air burping radiator while flushing, yes I did this when back flushing the radiator upside down. Shop vac to what would be the in pipe water to the out pipe and a flex tube fed in through the drain cock hole with the engine upside down ran the water at full tap flow in and kept moving the flex tube in and out of the tank so that it would move the stream of bubbles around no crap came out.

Ran the engine for nearly an hour today. Air temp in the shop when I start was 80F/26C (hot day here) very quickly the shop air temp jumped to 90F/33C. Ran the engine for 30 minutes with the cleaner in then 30 minutes with drain out and cold tap water going into the top tank to make up what was coming out to clear the flushing agent out. Running the engine at 2000RPM it climbed to about 190F and on the water jacket sensors and about 205 on the top tank with IR gun, but no higher.

Interesting to watch the temp gauges with the engine not running but the blower fan still on the engine continues to circulate, thermosyphoning causing good circulation. (to insure some flow with the thermostat fully closed I have added an 1/8" hole to thermostat body.)

Was going to do more testing but by then I was pretty well cooked standing around in the hot air blast coming through the radiator.

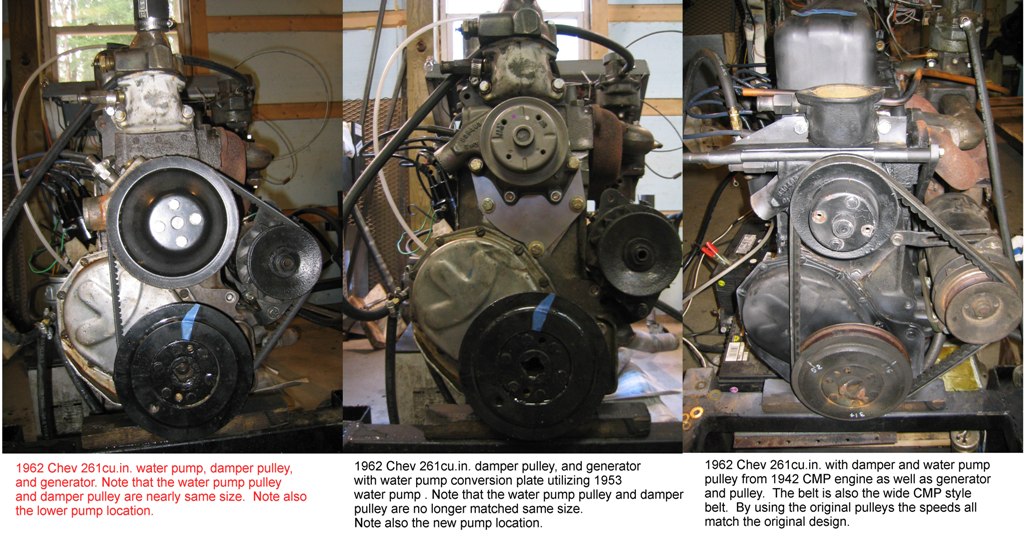

Think the next step will be to finish the conversion of water pump from the low mount position to the high mount to match the original fan location.

More details on pump swap from doing it on the 261

http://www.canadianmilitarypattern.c...ifications.htm

Looking at these photos, it reminds me that I need to check the pulley sizes back to the original engine on the Pat 12 engine just to be sure that in the process of swapping out the original unusable 216 engine for the one that is in it now that I didn't in inadvertently mess up both the water pump and fan speed.

Ah the mysteries of CMPs.

Thanks everyone for taking time to read this thread and add thoughts and suggestions.

Cheers Phil