|

|

#1

|

|||

|

|||

|

Text removed as content is no longer current.

Last edited by Stuart Fedak; 05-10-17 at 21:10. |

|

#2

|

||||

|

||||

|

Stuart,

Interesting subject. I just came across a complete DAF 4-ton GS truck cargo bed for sale. It would be a great place to store a jeep. HTH, Hanno Quote:

__________________

Regards, Hanno -------------------------- |

|

#3

|

|||

|

|||

|

I have used modular tentage as temporary structures. The canvas can be had cheaply and if you find whoever buys the scrap metal from the local bases, often repairable modular frames can be salvaged. The key to surviving windstorms with modular is to secure every leg to the ground with stakes, and to tie off the peak of both ends with a guide wire to the ground. plenty of railroad ties on the flaps help keep it all in place too.

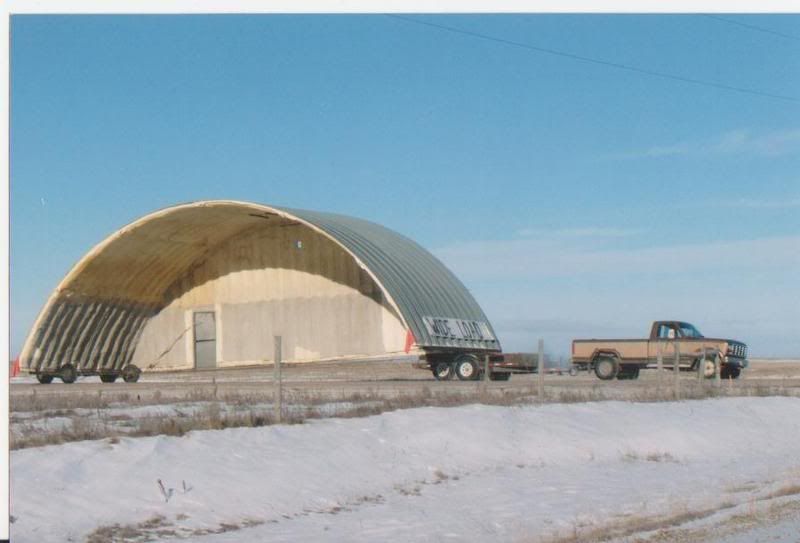

I recently bought a batch of mod tentage from the DND and for about $600 I got 40 salvageable centers, numerous fronts and rears, ten of the 10 man arctic tents, and a few other goodies in the pile. Of course, if you are in an upscale community, the neighbors may frown on such a structure on the front drive. To this, I say, get thee out to the country. Here is a photo of (one quarter of) another more permanent structure as I dragged it home from the local base a few years ago. Real cheap, and the work kept me busy for a few weeks.

|

|

#4

|

||||

|

||||

|

HI

You were allowed on the road with that

__________________

Eric Thibodeau 1942 willys Jeep |

|

#5

|

|||

|

|||

|

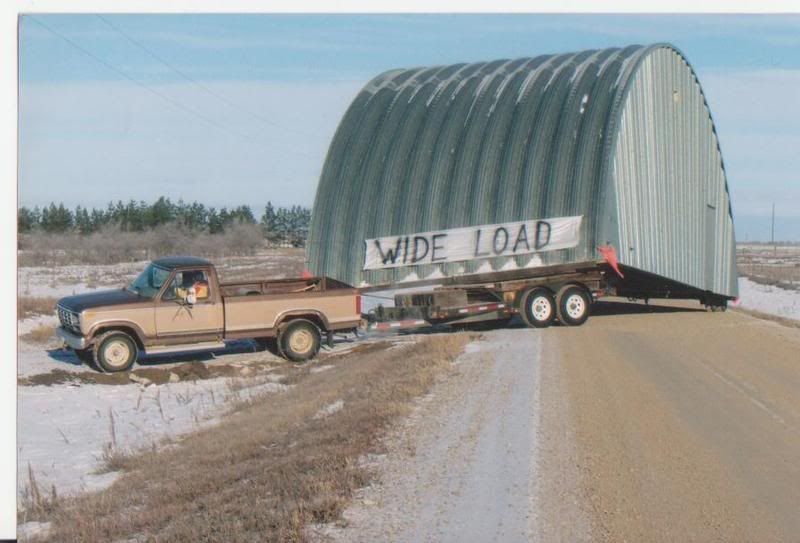

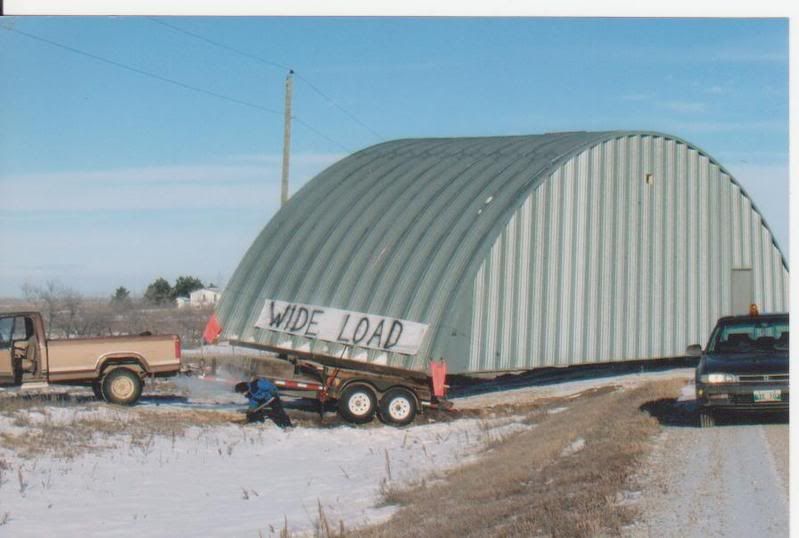

Yes and no. I went at the last minute to the highways department to get an oversize permit. I had to go all of about 3 miles on the highway to go from the base to my property. Of course, their answer was no, and in anticipation I had already recce'd a much longer route using only grid roads. I went 8 miles that way, followed by a cross through a ditch and across my neighbor's acreage. I had hydro come check the route for line clearances, and they actually followed me for the first trip. Cost for them was $40. All four trips went without a hitch.

Grid roads don't fall under the Dept of highways authority. The municipal office didn't care, although they initially thought I would have to go to the area planning for a building permit. I informed them that my intention was to use it for agricultural purposes, to which we both knew there were no permits required. Below are two photos of the last portion of the whole trip. First photo is crossing the ditch over a quick approach I threw in (30 yards of gravel). Second photo was where one wheel went over the edge. A bit of quick shoveling and I was back on my way.

Last edited by rob love; 15-02-10 at 04:26. |

|

#6

|

|||

|

|||

|

|

|

#7

|

||||

|

||||

|

Rob,

They are still talking about that project of yours here.If they ever try and tax you on the building you can honestly say it is a portable building and I can move it whenever I want and I have pictures to prove it! Do you still have that old Ford truck or did it go to pasture? Derk.

__________________

1942 Ford universal carrier Mk 1 1943 Ford 60 cwt long CMP ambulance 1943 Ford GPW 1/4 ton stretcher jeep 1943 Bantam T-3 1/4 ton trailer BSA folding airborne bicycle ser#R5325 (early) |

|

#8

|

|||

|

|||

|

We now have 7 shelters at the farm.

The early one from Princess Autowhere beige/tan colored and last the longest....3 to 4 seasons or should say years as we do not remove them for the Summer. Last few years the quality of the silver tarps from PA is plain awful.... one season is all you will get from the siver tarps...... so we buy replacement siver tarps at PA for about $40 when on sale (24x16)....some shelters now have 3 layers of tarp. We never had one collapse but we do have a snow patrol.... I inspect the accumulation and let out an email for clean up..... easiest has beento push the inside with a traw broom..... on a cold day your hand is too small an area and can actually punch a hole in the roof..... The other disadvantage is that all the snow you push off the roof falls on each side and will accumulate tot he height of the roof line....... from expereince we now leave just enough room between shelters fro me to back up the 7 foot wide snowblower and clear the area. Failure to remove snow from the side will eventually ice up and push in the side walls to a point of failure. If I had to buy new temp structure I would favour the better quality Shelter Logic models sold by Canadian tire..... made in New England sate.... tarps are 2 to 3 times heavier..... roof is domed instead of flat pitch.... and are design to withstand snow better...... they are also taller by design. CTC sells them $600 but regualrly on sale at $400. Don't be too concerned if the model you select is marginally not high enough for a CMP....... to anchor the shelter use old railroad ties..... you gain about 8 inches...... and they give you a place to lag bolt the shelter pads into something the wind will not lift. For extra protection we usually tie the shelter roof peak with rope to the vehicles stored inside... like wearing suspenders and a belt. We are hoping to get some sea containers in the future and span the space between them for more storage.......but most likely will still need the flexibility of cheaper shelters...... So far, in the rural areas, temp shelters have not been a by-law issue. Boob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#9

|

||||

|

||||

|

My (silver) PA shelter at the Hammond Barn has had a tarp added for extra protection but the one at Don Dingwall's back yard didn't and it 'blew apart' last week. I think that I will invest in a Cdn Tire model this summer.

__________________

Those who live by the sword will be shot by those of us who have progressed. - M38A1, 67-07800, ex LETE |

|

#10

|

|||

|

|||

|

You can actually skin it twice...once on top once inside..... keep the space in between inflated with a small blower.... instant insulated green house.....

Unless you use pressure treated plywood it eventualy rots and fails.... for our purpose with proper ventilation...single skin it would work.... so would a pole barn construction..... rigid frame.... sheet metal roof and canvass siding... What it really boils down to is do you spend $3000 for a very secure 8x8x20sea container that you can use as soon as it hits the gravel bed.... estimated life.......25 years.... or $1000 for a rugged 10x7x20 HD canvass shelter that requires 8 hours to set up good for 10 years....... or a $500 do it from scratch project that will consume 3 weekends and last 5 to 10 years.... the big cost is quality UV resistant covering..... Frankly at my age, with all due respect to practicality, if I can get a middle of the ground solution for 10 years with minimum efforts to set up and to maintain....... $1000 for ten years is $100 a year.... after that my needs to shelter a wheel chair will be minimum..... I found this Canadian company from NB....Cover tech...... looks promising.... There may be others....but bottom line is that for a quality 7x12x20 average costs is about $1000..... if it will last 10 + years....ain't so bad. Boob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#11

|

||||

|

||||

|

Hello MLUers,

When I worked in Parks and Gardens in Queensland we made a modular hot house which had a lightweight metal frame which could be dynabolted down to concrete blocks; or if you wanted bolted into concrete footings in the ground. The sides of the vertical posts and the pitched roof had "C" shaped channels. The metal frame was made up of two posts and a centre flange which the pitched roof went either side of and then bolted to the posts. Then waterproof film which had circular ribbing sewn into its sides was fed through from the bottom of the "C" on one post up over the roof pitch and down the other side. Dishwashing liquid really helped you feed in the film through the "C"s. To keep the frame strong and the film rigid a number of horizontal spans of metal secured the film to the base of the posts.They also used wire and turnbuckles to make everything rigid and it was rated to be very windproof. The units were originally designed to provide temporary housing for disaster areas in Asia as they were waterproof and could stand up to strong winds. If you wanted to expand the structure you just bought more waterproof film and more metal frames. They were designed to be fully transportable so they could load into small planes and once they landed they were light enough to be transported by animal or human powered village vehicles and taken to where they were needed. All you had to do to shift it once it was no longer needed was slide the film out and unbolt the metal frame, roll up the waterproof film and throw it in the back of a truck or trailer and flown out to be stored and taken it to the next place it was needed. Kind Regards Lionel

__________________

1940 Chevrolet MCP with Holden Built Cab (30 CWT). 1935 REO Speed Wagon. 1963 Series 2A Army Ambulance ARN 112-211 Series III ex-Military Land Rovers x 2 |

|

#12

|

||||

|

||||

|

I just remembered that the film panel (between the two posts) also had a window each side. Insect screen was sewn permanently into the panel and the windows had a zipper. So you had ventilation and when it rained you could zip up the window flap and it stayed waterproof. End panels and sliding doors finished the job to make things snug.

Kind Regards Lionel

__________________

1940 Chevrolet MCP with Holden Built Cab (30 CWT). 1935 REO Speed Wagon. 1963 Series 2A Army Ambulance ARN 112-211 Series III ex-Military Land Rovers x 2 |

|

#13

|

|||

|

|||

|

Army surplus modular tentage on aluminum frames is OK for small low vehicles, but it isn't all that tall for the bigger ones.

I have a name brand driveway shelter (Tempo) and its advantage over the Princess Auto model is spare parts. Two winters ago there was about 4m of snowfall, and my beloved was struggling to keep the important parts clear. The shed collapsed, and so did most of the neighbours'. I helped them tidy up and collected a fine selection of poles and fittings, then sold the remainder as scrap steel. I only needed to buy the critical angles from the factory. Try that with something made by the 'supplier of the month' at Princess? The back 2 bays of my shelter resemble one of those boat covers. I made mine with rough lumber and of all things, the vinyl media from a Marlboro cigarette billboard ad that my brother cadged off a shooting buddy. Any strong fabric will do.

__________________

Terry Warner - 74-????? M151A2 - 70-08876 M38A1 - 53-71233 M100CDN trailer Beware! The Green Disease walks among us! |

|

#14

|

|||

|

|||

|

Quote:

Something I am going to try this summer is to install the canvas inside out on a mod tent. The insides of mod tentage are now white while the outside is still the usual green. By putting it up inside out I hope to reduce the heat requirement and at the same time make it look less like an army tent. |

|

#15

|

||||

|

||||

|

G'day MLU'ers

The height on the temporary housing could be however high you wanted. All you need to do is choose a suitable height for the posts and cut the film to fit. It was aluminium framing that was 100 x 50 mm and the structures were actually cyclone rated. You could also use film with a reflective coating to keep them cool in summer. I am not sure how the structures would handle snow as it is not much of an issue in Asia where the shelters were designed to be used for emergency housing after a natural disaster. They were for a possible UN contract which they lost because the structures were too dear. So having paid for the patents the company decided to branch out into building horticulture structures as there was more money to be made in that area. I think the company no longer exists. Kind Regards Lionel

__________________

1940 Chevrolet MCP with Holden Built Cab (30 CWT). 1935 REO Speed Wagon. 1963 Series 2A Army Ambulance ARN 112-211 Series III ex-Military Land Rovers x 2 |

|

#16

|

||||

|

||||

|

Bob and Clive, thanks for the update on the PA silver tarps. I have an old one that has been outside for 7 or 8 years and if it wasn't for the mice it would still be good. I was going to buy a couple of PA tarps on sale, starting today, but after your posts I will rethink this. I know the blue ones last about 15 minutes.

Cheers, Barry

__________________

Every twenty minute job is one broken bolt away from a three day ordeal. |

|

#17

|

|||

|

|||

|

Hi Barry

My first PA tent was tan and lasted about 3 years...... the silver tents use to last two full seasons....... now it seems that the silver application flakes off before the season bearly ends...... what you have left is a rag type weave that will absorb water.... freezes and then becomes brittle. Even on firewood piles I could count on 2 to 3 years use... n ow one summer and they are rags. The blue or green ones are even worst.... I covered furniture on the pickup.... halfway down from Toronto it started to fray and came apart. The heavier 14 oz. poly tarps of the quality Winter garage are heavy as hell but they seem to last a lot longer...... some trailer storage outfit near my place have had some for 3 to 4 years ands still look new. Boob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

| Thread Tools | |

| Display Modes | |

|

|