|

|

#301

|

||||

|

||||

|

I am pleased with the look & function of rifle clips. The felt stops any contact with painted surface, as I had hoped. Bloody good thing I did it too, because the metal strap band on the SMLE would have been damaged & taken the paint straight off the clip! As Rick said 3 days ago, the rifle butt does not sit flat at the bottom. I am concerned if all pressure is in one place, the rifle may get damaged with the bouncing of the truck, so once the blocks are made for the butt to sit in (I know what you're thinking, don't say it!), I will add a layer of thick felt to the inside of the base. There is a 7mm thick material that Podiatrists use, called simply "Podiatry Felt", surprisingly enough!. It is adhesive on one side, able to be carved or shaped with knife or scissors, and the correct profile can be made with this. You can also use it to take pressure of corns or bunions on your feet, just in case you wanted to know

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#302

|

||||

|

||||

|

Felt shouldn't be out of place, my but holders are tin rectangles with 10mm of felt riveted all round and in the bottom to cover the bolt heads.

__________________

Robert Pearce. |

|

#303

|

||||

|

||||

|

Were those metal boxes a Chevrolet item, or was it 'luck of the draw' which trucks got them?

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#304

|

||||

|

||||

|

as far as I know it is an after a certin date thing as I have seen pictures of Chevs built before mine with the wooden but holders.

__________________

Robert Pearce. |

|

#305

|

|||

|

|||

|

Hi

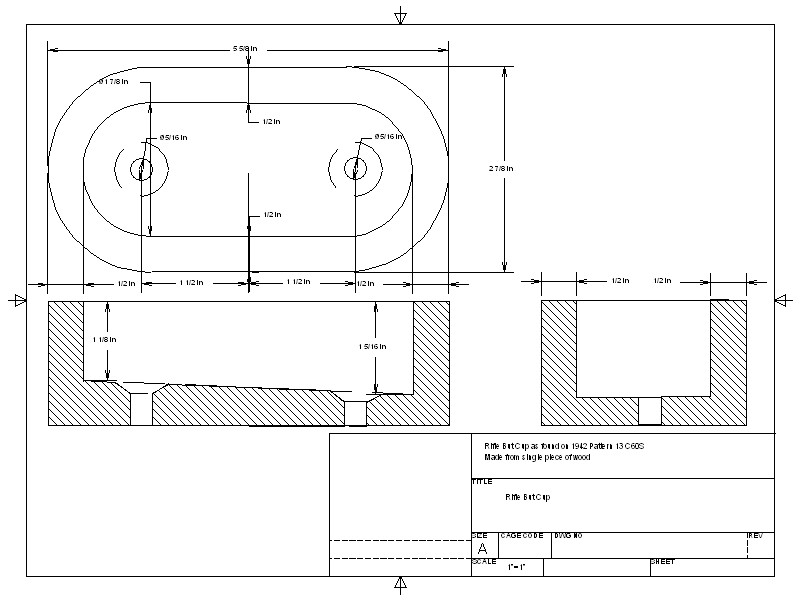

Here are some photos of the rifle clips on my 1942 Pattern 13 C60S. As mentioned the cup is sloped to be deeper at the back. I've got dimensions if anybody wants me to post them. Now a question, what do you do for units using the No5 Mark I (jungle carbine)? Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#306

|

||||

|

||||

|

Quote:

They have a high tendency to rust because the felt conveniently holds water against the steel.

__________________

Film maker 42 FGT No8 (Aust) remains 42 FGT No9 (Aust) 42 F15 Keith Webb Macleod, Victoria Australia Also Canadian Military Pattern Vehicles group on Facebook https://www.facebook.com/groups/canadianmilitarypattern |

|

#307

|

|||

|

|||

|

Quote:

Yes, I would be interested to see at least some of the dimensions from your blocks. Bob recently sourced a NOS butt block that was smaller than the dimensions published in Convoy Magazine several years back and some old and weathered blocks are yet other sizes. (Bob's NOS didn't have a drain hole but Convoy dimensions one and some of the weatherd blocks have one.) I don't know if this is a case of different contractors working to different dimensions or different designs for different uses or just sloppy manufacturing but you would think that at least the inside length and width of the block should have been standardized along with the spacing for the mounting bolts. The mounting spacing does seem standard but other aspects vary. |

|

#308

|

||||

|

||||

|

Phil,

The issue with L.E No. 5 is an interesting question. I have a Jungle Carbine here & while i've not yet tried this on the rifle clips, I would expect it to be too short for the clip to grab. Also the butt plate with strap loop might be too wide for a regular floor block. On the other hand..........at least it has its own 'padding' on the butt  I'll test this fit later today & let you all know. And YES, I would also like to see the dimensions you have there.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#309

|

||||

|

||||

|

The Australian designed gun tractors No8 and No9 have provision to fit a bren gun up in the roof and a smaller machine gun on the driver's mate's wheel arch. Here's how the box for the butt was fitted. You'll also notice the 'glovebox' for ammunition. This pic is on the AWM's FGT No9.

Quote:

__________________

Film maker 42 FGT No8 (Aust) remains 42 FGT No9 (Aust) 42 F15 Keith Webb Macleod, Victoria Australia Also Canadian Military Pattern Vehicles group on Facebook https://www.facebook.com/groups/canadianmilitarypattern |

|

#310

|

||||

|

||||

|

Keep up the terrific work Tony and keep the pics flowing.

Your thread is great to follow and an eye opener. This Blitz will get plenty of this  once it's done I'm sure. once it's done I'm sure.

__________________

Blitz books. |

|

#311

|

|||

|

|||

|

Hi All

Here is a quick drawing of the wooden rifle cup on my `42 Pattern 13 Cab C60S  Concerning the Carbine, always wondered if you reversed the upper holder down would it fit the Carbine. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#312

|

||||

|

||||

|

Great tech drawings Phil, thankyou. Also thanks for the photos prior. I have yet to catch our woodwork museum open, but will print a copy of these to take with me when I go next. I'm confident someone there will get involved and make a couple of these for me. Those fellows are mostly craftsmen from another age, when things were made to last!

Thanks to you too Keith, I have copied that photo of the MG butt holder & 'glovebox'. I wouldn't mind making one of those gloveboxes, actually  . .Yesterday was quite unproductive. I got 90% of the side curtain frame jig completed, but stopped when I was about to make a silly mistake with welding something in wrong place. I figured it was time to put it away to continue fresh another day. I did clean-up some minor electrical bits, but nothing worth photographing. The Jungle Carbine DOES fit in the clip, but it is sloppy fit. At least it is sloppy without the wooden block for it to sit in. I have not measured against the dimensions Phil posted, to see if it would sit down inside, but will do so when I get the chance.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#313

|

||||

|

||||

|

Here's the 'funny story' I promised a week ago.

Remember those NOS Ford CMP Tail/Brake lights on ebay a number of days ago? I bought a set for myself. I won't upset anyone by stating the purchase price, suffice to say that I am VERY pleased with the transaction.  These may prove to be my treasured 'Purchase of the Year'!

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#314

|

||||

|

||||

|

Quote:

__________________

Regards, Hanno -------------------------- |

|

#315

|

|||

|

|||

|

Good score Tony, Well done!

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

#316

|

||||

|

||||

|

If my calculations are correct, he still has another set to sell.

On the expected sale price, I thought they actually went quite cheap. First one = $128 & second= $120. Two people considered they were worth getting  If it makes you feel any better........the "Ford Canada in Wartime" I won, hasn't arrived yet. That might equal things out

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#317

|

||||

|

||||

|

Drivers door is back from the blasters today.

It is VERY straight. No dents or collision damage at all on outside, but.... There is someone out there who welds worse than I do! And I'll be doing a bit of my own welding, in addition to 're-repairs'. I have the missing bit of metal. It's somewhere in the old shed.  The workshop hadn't been built when I stripped the hardware off the door. Bought a new, good quality grinder on Sunday. Timing is perfect. The remaining hinge bolts (one on each hinge) are actually held in place with some of the weld from the previous repair attempt.  Better get a new roll of CIGweld wire for the MIG!

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#318

|

||||

|

||||

|

Quote:

Maybe I should make some repro sets and flog em off for some profit  What is the dimension across the hex section ? I can buy some hex mild steel and turn it down .... MIKE

__________________

1940 cab 11 C8 1940 Morris-Commercial PU 1941 Morris-Commercial CS8 1940 Chev. 15cwt GS Van ( Aust.) 1942-45 Jeep salad |

|

#319

|

||||

|

||||

|

Passengers door loses weight tomorrow. I'm getting a bad feeeling about this one  Better buy a second roll of MIG wire. With rain calling a halt to play Sunday, I got curious what a headlight reflector would look like, painted fake chrome silver. Short answer..........not good......not good. I'm using blackout lights, so I was tempted to do this instead of paying >$200 EACH for re-silver, but I am reading up on electroplating DIY. Shouldn't be that hard. Finally got around to cleaning off the headlight dress rims. Light sand & etch primer was all that was needed. I resisted the urge to attempt removal of two small dings in one rim.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#320

|

||||

|

||||

|

Your wish is my...well you get it!

Measurement across flats of the hex is just a 'bees dick' over 1", aka 25.5mm. I think they are aluminium. Well they are some light white metal, anyway. Are you meant to rub off the paint over the lens, or is that meant to be retained? I have seen some of these (in photos) where one side of vehicle has only one light, and a space where the other light should be. Is that normal? T.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#321

|

||||

|

||||

|

Quote:

Aluminium is easier to machine ... don't know if 1" hex stock aluminium is available . It's possible to machine that hex shape out of round stock using a milling machine and a dividing head - but it is a somewhat slower process . Mike PS it is available in the USA .... http://www.onlinemetals.com/merchant...745&top_cat=60

__________________

1940 cab 11 C8 1940 Morris-Commercial PU 1941 Morris-Commercial CS8 1940 Chev. 15cwt GS Van ( Aust.) 1942-45 Jeep salad Last edited by Mike K; 19-03-12 at 14:15. |

|

#322

|

||||

|

||||

|

They're die cast, not aluminium. On the rear there was only one stop light on the right so that is normal.

Quote:

__________________

Film maker 42 FGT No8 (Aust) remains 42 FGT No9 (Aust) 42 F15 Keith Webb Macleod, Victoria Australia Also Canadian Military Pattern Vehicles group on Facebook https://www.facebook.com/groups/canadianmilitarypattern |

|

#323

|

||||

|

||||

|

Maybe thats why so few of them survived intact . Die cast parts are fragile . Are they made in two sections threaded together ? I recall having one years ago , it screwed apart to access the globe from memory ??

__________________

1940 cab 11 C8 1940 Morris-Commercial PU 1941 Morris-Commercial CS8 1940 Chev. 15cwt GS Van ( Aust.) 1942-45 Jeep salad |

|

#324

|

||||

|

||||

|

Mike, thats exactly how they come apart. Here are two photos I took several days ago, for reference purposesl.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#325

|

||||

|

||||

|

OK

what is behind the bracket ? eg, What holds the globe holder into the steel bracket ?

__________________

1940 cab 11 C8 1940 Morris-Commercial PU 1941 Morris-Commercial CS8 1940 Chev. 15cwt GS Van ( Aust.) 1942-45 Jeep salad |

|

#326

|

||||

|

||||

|

The same hexagonal profile is behind the threaded portion, and this is larger than bracket hole. This would allow spanners to tighten/loosen the assembly body. The same action secures light in the bracket hole. Quite ingenius, two things done with one action. If my set is anything to go by, there is NO rubber seals around the thread to keep water/dirt out. I'm sure I can provide that when time to install!

The seller these lights came from has one final lot on ebay. It is only two lamps with one bracket, but would be good enough for a pattern. $50.00 buy now. I thought about getting them myself, to use as front guard lights, but I am a long way from that stage yet.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#327

|

||||

|

||||

|

I bought this piece of wiring, which was identified as C11Q-14403. According to the parts manual, C11q-14403 should be a Ford harness for headlight & horn. It looks a little too complex for that! Is it really that part? At $5.00, I was happy to take the punt anyway.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#328

|

||||

|

||||

|

Quote:

There's also a cab 13 version, same number with C29Q prefix.

__________________

Film maker 42 FGT No8 (Aust) remains 42 FGT No9 (Aust) 42 F15 Keith Webb Macleod, Victoria Australia Also Canadian Military Pattern Vehicles group on Facebook https://www.facebook.com/groups/canadianmilitarypattern |

|

#329

|

||||

|

||||

|

Andy,

These are the grease seals we were talking about. Total length - 45mm Diam of small hole - 15mm Height - 21mm Diam of large semi-circle is 26mm The thickness of the rubber in large curve is 3.5mm (ish) for most of the length, but one end is slightly thicker. Possibly a subtle design included to create better seal on the lower end. Take that, gravity!!!! Hope this helps.

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

#330

|

||||

|

||||

|

I had an SMS from the sandblaster this afternoon. The second door is blasted & ready for me to take. Hopefully they will be working tomorrow morning, or it will be next week before I can look at it. Regardless, there is plenty of work to be done on the drivers door, and that may take all my time this Sunday anyway.

I made a point of buying that CIG brand roll of MIG wire. I have had good results with that brand. Not so much with others. As a fairly inexperienced, amateur welder, I need all the help I can get. If I get to an impasse with the door, the next task is to examine window glass frames, and choose the best I have for repair. I have some really bad ones that I won't feel guilty pulling apart to examine construction method or to experiment repairs with. Just a little while ago, I was reading some MLU postings on another thread, regarding use of molasses in de-rusting parts. I would like to give this a go for something in near future. Maybe this might be a good thing to drop the window frames into. I don't fancy trying to get those frame screws out without some serious chemical assistance. Can't use heat because the glass is too good to destroy. Molasses is easy to get around here, so I may even get some tomorrow while in town. Doubt I will be saving any for the morning toast though. With another week passing without hearing from the bolt shop, I guess they will get a visit as well. Where did good customer service go????? On a much sadder note, I happened to be passing through Kandanga this afternoon, at the same time a funeral memorial was ending. It was the funeral of a little 12 year old local boy, Jake Garrett, who had passed away early this week, following an accident he had while on a ride-on-mower. The poor lad had been in an induced coma at the childrens hospital in Brisbane for many days, and his injuries were numerous and of such severity that they were ultimately not compatable with life. As I was passing the hall where the service had been held, I heard the uncontrollable anguished screams of a child, perhaps a sibling or friend of the deceased. I have had both the honor and the curse of attending many funerals, Civillian, Military, young or old, but the sound I heard today is one that will stay with me all my life. Just when you think you're hardened to suffering and death, something like this comes along and jolts reality back again.  http://www.sunshinecoastdaily.com.au...ight-for-life/

__________________

Ford CMP, 115" WB,1942 (Under Restoration...still) Medium sized, half fake, artillery piece project. (The 1/4 Pounder) |

|

| Thread Tools | |

| Display Modes | |

|

|