|

|

#91

|

|||

|

|||

|

Hi All

Well my progress on the HUP seems to have slowed to a visual stop. Body and parts work has progressed to the point where I have a lot of painting to do and it just has not been practical to paint even though I have set the shop up with flow through ventilation. But the real problem is that to paint I have to move the other two trucks out side an the never just has not cooperated to park them out side for a week while I paint. Progress - Been running the rebuilt engine in on the test stand, it starts and runs nicely and will idle all the way down to 400 RPM. Tone of the engine is nice and smooth at all speeds. Haven't got the low range tachometer yet but did pick up a (small diameter) tach on sale, which is a nice add to the test stand. Next step on test stand is to find an oil pressure gauge which is full sweep at like 60. But before I do I'm going to hitch all the different pressure gauges I have up to a single pressure source and see if they all read accurately, or at least agree.  Running engines in on the test stand during the winter has some real advantages it heats the shop up nicely. (The exhaust hard piped out of the building plus I've got good digital read CO2 alarm in the shop.) Added a second temperature gauge to the test stand so that I now can read both rear of the block and at the water pump to see if the block is evenly cooled, which it is. The forward water pump location for the sensor is also a good location to consider for temperature sensor if you are using a different head which doesn't have the large fitting hole for the steam relief and sensor fitting.   List of minor stuff to fix on the engine as result of test running, minor coolant leaks at rear drain cock, thermostat housing, minor oil leak side oil cover though to really fix that one I'll have to remove the head and get the block and head truly aligned. Yup I missed these on assembly.  More progress to come soon, I hope. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#92

|

|||

|

|||

|

Quote:

Tim Tygart www.obschevy.com Jimmy Carter www.oldchevytrucks.com Larrowe www.34-chevy.com and Chevs of the 40s www.chevsofthe40s.com all sell insulators that look like the ones Classic Parts is selling. I sourced an insulator for Bob from one of the 4 I listed and it seems satisfactory. |

|

#93

|

|||

|

|||

|

Hi Phil

Got my spacer from Carter....Jimmy for his friends. I suspect they all come form the same offshore suppliers and retailed by all the Chevy parts source. Mine worked fine..... but I have to make sure I get the large bore and bolt size.... the 261 is 2 15/16 for the bolts and the large throat. On the oil fog...... I lost my dip stick from the diesel MF Perkins engine and oil was spewing out of the dipstick tube like you would not believe. Called the dealer for a replacement and expressed my concern that the engine was probably gettign serious blow by and might need rebuilding.... he re-assured me that on those little 4 cylinder long stoke engines the air / oil fog following around inside the crankcase was standard and normal and very much part of the cooling and lub of the bottom end... so you concept of a heavy oil fog churned up by the rotating crank is well founded. Felt like a fool for loosing the dip stick ... apparently I was the second one he sold in a week..... so did not feel so bad..... Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#94

|

|||

|

|||

|

Hi All

Well after several months of work on the HUP which never seemed to show any progress to completing the over haul Visible Progress Resumes. My real problem was I go to a point were almost everything was being held up my needing to paint major parts. Though we still had snow left from plowing at the beginning of the week the snow is now gone and we are having high 70s low 80s F weather. First step was pulling the HUP chassis out of the other garage where it has been sitting all winter. I move it to the garage bay that normally houses my car to keep it clean as I continued to work on stuff in the shop. As you can see from the photos of the divots left in the door yard the ground is still soft. Though this was going to be a major undertaking but in the end once I go HUP turned I was able to tow it and push it in to the main shop, even got it centered in the bay on the first try. Off with the wheels and a little cleaning and it was ready for the flat coat of OD which I sprayed on today, tomorrow I hope to put the wheels back on and get ready to lower the body back on. Then the really serious reassembly can begin again.

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#95

|

|||

|

|||

|

....one man show.

Been getting the same warm weather up here.... what a pleasant break. Actually did a small bit of sand blasting last weekend. Finding that some of my cab 11 sheet metal had been trimmed and modified with a hot torch. In the process of establishing how much had been removed by inspecting similar parts on the other cab 12 Grant and I concluded that we had better spare parts from a cab 12 that needed less repairs........ did I not say in the past that you cannot restore a truck without two or 3 spares for parts...... Noticed some interesting differences in the inner fenders and floor plates of certain cab11 / 12 will follow up with pictures on the Hammond barn site. Cheers Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#96

|

|||

|

|||

|

Hi All

Oh how good it is to see visible progress again, body went back on and is now all bolted down to the chassis. Put a layer of plastic sheet in between the chassis and the body so that I don't have to keep masking the chassis as I prime and paint the body. Once everything is in place I'll just cut the plastic out. Now to the lesson of the day. KEEP ALL YOUR PARTS ORGANIZED when I disassembled the HUP I was fanatical about boxing, listing all the parts on the boxes, and putting the boxes away on the shelves in the loft of the shop. But during the process of cleaning and painting individual parts not everything got put back on the shelf. Big mistake, spent an hour searching for the wood frame spacers found them in the end but it would have been easier if I had put them back in the box they were listed on. Another restoration tip, as I work bolting parts on I keep my camera ready to take photos of anything I've missed or areas that need to be repainted. These are going a photo file of things to follow-up on quicker than making shop notes of every spot that needs to be repainted. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#97

|

|||

|

|||

|

The next vehicle I restore, I'm going to resist the temptation of the rapid dis-assembly. (They all come apart quickly.)

Instead I'm going to clean each individual part as it comes off. Once cleaned I will determine what work is needed and lead time on getting parts. Then before boxing it I'll create an inventory on the computer of what box on which shelf it is located. Along with adding any parts need to the computer list of what parts need to be found. Then as major component engine, drive train, body etc are disassembled and cleaned I will prioritize the parts and overhaul schedule. Well you get the idea. I can dream can't I. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#98

|

|||

|

|||

|

...to bag everything and box everything....and was partly successful....but I still need to look for parts.......

At the barn I have this great system...... when I am finished with something I usually very carefully put it away some where very secure so I will not loose it..... than 6 months later I can't remember the secure place....... ....then I ask Grant ...Have you seen my spare E brake handle...? it was just here a few days ago..... a while goes by and Grant comes back and says I know where it is.... for $5,00 I can tell you where to find it. He will never be rich as he usually tells me where to find it...before collecting...... sure beats trying to get organise..... just have Grant around !!!! The other way is to go out and buy a repalcement then you will always find the item you where looking for. At least Phil you cannot blame anyone else for moving rro misplacing your parts. Wait until Al Zeimehr kicks in....... I will have the only CMP with a Pinto rear end..... Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#99

|

|||

|

|||

|

Hi All

Today's dis-assembly tip, that you find when assembling the parts months later or even the next day. Take a look at the picture below of the linkages laid out on the table. You should notice one thing, but might miss the second important thing but they are related. Well of course you will note that like almost all linkages on CMPs they are adjustable. What is missing from the picture though is a measurement of each one made before you disassemble them to clean them. What I now realize I should have done is laid them all on a piece of paper measured the overall length of each written that on the paper next to each linkage and then taken a picture. Which would have save me a lot of time get the linkages into adjustment when reinstalling them. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#100

|

|||

|

|||

|

Hi All

What do these two products have in common?  They both remove paint and strangely the one on the right seems to actually work better, is cheaper, environmentally more friendly. Washing soda has come up over the years many times on MLU for various reasons such as Restoration Tip: Electrolysis Derusting, degreaser etc. Well it was in the process of using it as a degreaser that its paint removing characteristics came out. Like with any degreaser they work better if the the part, grease and liquid are hot. So one day I throw bunch of grease small parts into an old electric fry pan with 1/2 cup of washing soda and gallon of water and left the whole thing to simmer for awhile while I did something else. The parts had a thick layer of grease on top of many layers of paint. When I pulled a part out of the simmering stew and when at it with a small wire brush not only did the grease come off but the paint as well. The pictures below show parts simmering, what they look like as removed and after a few minutes with a wire brush. Then spraying the parts with a good water based degreaser and washing the parts with hot water leaves them ready to paint. Tomorrow I'm going to try hitting them with hot water pressure spray see if that will clean small parts which are hard to wire brush. If that works got to find a bigger boiling tank. As to the Aircraft Coating Remover, found that this tends to only remove one layer of paint at a time. Comments and suggestions please. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#101

|

|||

|

|||

|

Quote:

I use that for oven cleaner also..The ingredient that is doing all the heavy lifting is sodium carbonate...sodium BI-carbonate will make you burp and will clean battery terminals but the sodium carbonate is the big lifter in Grandmas washing soda..

__________________

Alex Blair :remember :support :drunk: |

|

#102

|

|||

|

|||

|

.....still allows you in the kitchen unsupervised...?

Will call you...... Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#103

|

|||

|

|||

|

Just add your battery charger and it will also get rid of the rust

Good for everything Stew |

|

#104

|

|||

|

|||

|

Hi Stew

I have used washing soda in the past with power supply to derust parts works pretty good. But using washing soda hot at a higher concentration does a pretty good job of softening multilayer of paint and clearing some of the rust. Was reminded this morning that if you let paint on a part cool off and dry out the paint gets surprisingly hard again. Really should do some controlled experiments to see what concentrations, at what temperature work best. But that will have to wait until I have the HUP back together. Right now my priority is to gets those last bits that I didn't clean when disassembling cleaned and repainted so they can go back on the truck. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#105

|

|||

|

|||

|

Hi Phil

I have a 5 and a half foot x five foot high tank that I use and then use my welder for the power supply with 2 quarts of soda from Home depot and I can remove rust, paint , and what ever else is there in a few hours. Just make sure the connections are right or your steel ages and disappears into rust. For cleaning the roofs on the cabs I just lay down a plastic sheet , set up some blocks around it and fill with water ( like a mini pool) and Soda and the welder and it cleans them up real quick All you need to do is hose the parts down and brush them off It has worked for me for a lot of years Stew |

|

#106

|

|||

|

|||

|

Hi All

Well Summer Temperatures are back and I've been painting, like mad. With most major parts now primed and the first coat of color on. Plan to do the flat top coat after reassembly of doors, fenders etc.  While the paint was drying in this afternoons 90+F heat I also got to work on adding more pictures and text to website HUP Over haul pages and doing some revamping of the link structure. http://canadianmilitarypattern.com/index.html The home page/index has been updated to make sorting through what was done when easier. http://canadianmilitarypattern.com/H...11%20March.htm Covers March http://canadianmilitarypattern.com/H...12%20April.htm Covers April so far Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#107

|

||||

|

||||

|

You must have got through all that reading I sent you if your out painting..Great looking Job!

__________________

42 Slat grill 43 Ford gpw 44 C15A Wire 5 |

|

#108

|

|||

|

|||

|

Hi Jason

I'm reading through and enjoying, cross reading with other sources to see how changes took place. Thanks Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#109

|

|||

|

|||

|

Hi All

Well, Iím looking for comment from some of you who have restored 216 cu.in. Chevy engines. As you will know from previous posts I make it a practice of running engines on a test stand before putting them into the truck. I thought I was already to put the rebuilt original engine back in my HUP and was doing a long run (50 hour plus) on the engine to really get the temperatures fully equalized so I could do a finial adjustment of the valves. While I was doing this I noticed that at a low idle of 450-400 rpm the engine is only producing 5-6 PSI of oil pressure not unusual for 216s but, when I removed the valve cover I discovered that the oil flow out of by pass for the rocker arms was a lot less that what I every remember seeing. Flow from the individual rockers was OK but the total oil flow running out of the upper gallery is less than I remember from previous engine rebuilds. Here is the list of what was done on the engine that would effect oil pressure and flow:

What have I already checked:

If you wonder about the long test run on the test stand being a lot of fuel, it is but I manage to time my engine running to winter. With the engine exhaust hard piped out of the shop, running the engines is doing double duty, running in the engine but also heating the shop at the same time so Iím not burning any propane to heat the shop. Wanted to ask for comments before I start tearing the engine down. In particular how much oil have other people noticed running out of the rocker arm bypass tube in well run in engines? My memory is telling me it should be a good steady stream just under ľ ď diameter. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#110

|

|||

|

|||

|

The oil pump for possible air leaks on the sucking system......or attachment of pump to block....

Possible too much clearance on bearings....... the hard bearing to check for clearance will be the camshaft. You should be able to check oil pressure and all possible leaks by running the oil pump with a hi torque 3/8 or 1/2 inch drill with out running the engine..... that way you can check for large leak on crank. cam. valve train..... you may need to set up a larger oil container with a rubber tube from the pump to a 5 gallon can..... it will be messy....... cranking the engine by hand will also be feasible....... using the starter may prove to be dangerous as it will spin fast if the plugs are removed....... you engine stand will earn it money.... I got 42 pounds of oil pressure on my 261 using a hi torque screw gun...... Good luck....... keep us posted..... and wash you hands when you are finished. Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#111

|

|||

|

|||

|

Hi Bob

Good points Bob, I'm trying to see if I'm over looking something simple and to line up my thinking before taking things apart again. Your point about using the a drill to check the pressure and flow raises an interesting question what is the RPM of the distributor vs. RPM of the engine? I can not remember if it is one to one. As to the max pressure you mention for the 261 same for my 261 and 235 they basically max out at 42 psi though they will go higher on cold start with cold oil. Once the engine oil is warm the bypass in the pump itself starts dumping. Now I will have to check a 216 pump to see if same pressure max. Wonder if I should just change the oil, wonder if the combination of all the assembly lube or dilution. When I pulled the head to get a better alignment on the side gasket, I pumped several ounces of oil into each cylinder to prevent any coolant from getting into the sump. (see http://canadianmilitarypattern.com/H...12%20April.htm ) Because of how I drained and sucked the cooling system clean of coolant before removing the head there was no water in any of the cylinders when I pulled the head off. But I wonder if maybe I did dilute the oil with lighter oil? Your idea of hitching the pump up to external source of oil with pan off to see if the crank or cam are dumping oil is a good one. Messy but good. One of the reasons I wish the Hammond Barn was closer so I could just pop in and look at another 216 engine running with the valve cover off. But having said that I'll take the valve cover of the C60L after it is warm and see how much oil is coming through the bypass. As to washing my hands afterwards I always wear the blue rubber gloves. Appreciate your input.

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#112

|

|||

|

|||

|

But we would not be in this hobby if we wanted to keep clean.!!!!

Dizzy is driven by the camshaft gear and should run twice as fast as the engine crankshaft...... so a 3000 rpm drill is equivalent to 1500 RPM..... which is about mid range for the 216...more or less...... When I was priming my 261 with the drill and did not think that the pressure could get that high and did not bother installing hose clamps on the oil line to the external spin on oil filter..... big mistake,,,, the line came off....1/2 inch line .... and dumped half the crankcase oil on the floor before I could turn it off. Yeah I wish you were closer and we could both get down and oily together. One more reason for using a discarded CMP frame...... with the engine higher off the ground I could install a 5 gallon can below the engine with a light sheet metal trough wide nough to catch all the dripping oil and flow it into the 5 gal. can...... I would fit an extension rubber hose on the pick up from the pump where the screen fits....and clamp it so no air enters...... I would use the cheapest 10w30 bulk oil I could find.... and only use it for the test...... then I would recycle the oil in my wood furnace next Winter...!!! ...or you could just dump the oil you now have with possibly some dilution and fill it with fresh 20-50 racing oil...... and see how it behaves..... certainly worth the oil cost and effort at this stage...... You better get yourself the arm long rubber gloves used by vets... the short blue Nitryle ones will never suffice.... you will be going deep with this one. If you are going to test out the C60 try using the same oil pressure gauge to eliminate any gauge error. You are not about to get dry skin !!!! Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#113

|

||||

|

||||

|

Bob the camshaft runs at half the pace of the crank shaft in a four stroke engine.

__________________

Robert Pearce. |

|

#114

|

|||

|

|||

|

Hi All

New Topic for a moment, with several HUP restorations going on around the world at this time. Thought I would mention a fitting problem related to the gas tank and the running boards, possible rub or wear problem. The HUP family of vehicles like other CMPs mounts the gas tank on supports coming down and out from the frame. Originally there was a tar coated strip of fabric that went around the tanks to protect the tanks from wear from the support and the hold down straps. With the HUP family of vehicles the tank supports extend out to also support the running boards, that's the rub. While finishing up on fitting the fenders and side tank protection plates I happened to notice that the under side of the gas tank was just in contact with the edge of the diamond plate running boards. All that was touching was the high points of the ribs on the diamond pattern. Fix is easy increase the amount of strap padding on the bottom of the tanks. The contact was not great had not even scratched the paint on the tank but movement on the road my have caused problems. I mentioned this as once the side plates are bolted in place you can not even see the contact area. I'll post pictures later today. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#115

|

|||

|

|||

|

So if I am spinning the oil pump with a 3000 rpm drill...... allow for some 30% reduction for oil drag....... the oil pump is turning the equivalent of 4000+ engine speed.... am I correct...? that could explain my 42 pounds of oil pressure.

???????? Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#116

|

||||

|

||||

|

Quote:

__________________

Robert Pearce. |

|

#117

|

|||

|

|||

|

Hi All

Well I took the process of checking the Oil Pressure and Flow to the next level. First I confirmed that the distributor shaft and hence the oil pump drive makes one revolution for each revolution of the crankshaft. Then I brought the engine up to operating temperature which is 170 F with ambient air temperature of 75-80F this is with a 180F thermostat. I shot video of the engine oil flow in the valve gallery at various RPM levels. In the photos below you can see the differences. Then I changed the oil and did a new set of videos. Which is when I noticed what I think is the problem excessive oil flow from the rocker arms. The shafts are new but the individual rockers are the originals. It was looking at the video and stopping it and going back and forth that really clued me into what it the problem of. Take a look at the Video http://canadianmilitarypattern.com/R...stem%20DSL.wmv Still looking for input but I think it is worth putting the engine in the truck, road test it. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#118

|

|||

|

|||

|

Granted there seems to be a large amount of oil flow on the rockers....

..... but let's go back to the beginning of the oiling system..... The rockers are the lasts step in the oiling process...... first the crank, camshaft and then to the top of the engine where it eventually get dumped in the return channels/holes in the head back to the crank case. If all the other bearing clearances are tight or at least according to specs. the oil pressure doesn't really start to fall until it reaches the loose rockers... .... the oil pressure sensor is located early in the oil galleries... then why would it be so drastically affected by a leak further down into the system.... Is there anyway that you can reduce the flow to the rockers to confirm that the looseness of the rockers are in fact affecting the overall oil pressure??? some kind of temporary restriction inside the line...? If you can confirm that the rockers are at fault it would be relatively easy at this stage to correct before installing into the truck..... Now some rockers can be bored out and brass sleeves installed... not sure if that is feasible on the 216..... so rocker tubes are new and rockers as is.... it would not be too complicated to measure for clearance..... When you got your NOS head did it have the full valve train or was it bare....? If you need rockers I may be able to help you out...... how similar are they between 216 vs 235 vs 261...... 235 and 261 are usually interchangeable but not sure if low pressure 235 would interchange with high pressure 235 rockers Keep us posted... Bob

__________________

Bob Carriere....B.T.B C15a Cab 11 Hammond, Ontario Canada |

|

#119

|

|||

|

|||

|

Hi Bob

Good idea about isolating the rocker arm assembly to see what it does to the oil pressure. Think it can be done fairly easy, if that makes the pressure jump up then that is fairly easy to rectify. Couple of choices, as you suggested, I've got the bushings to bore and bushing the rocker individual arms, but a complete new replacement is $250. Plus I've got another used assembly that I think is good condition. I'll try isolating the supply today, if that identifies the problem then great, if not then I think the next step will be to drop the oil pump, or brink the 216 that came out when I swapped over to the 261. I kept it complete so it would be a half days work to get it all set up again. Don't think there is a suction leak because there doesn't seem to be any air bubbles showing in the oil. Just the normal air bubbles as the last of the air is pushed out of the oil filter even with filling the filter body with 2 quarts of oil before putting the cover on. By the way I recovered all the oil from the oil change into clear bottles and there doesn't to be any large chunks of stuff. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

#120

|

|||

|

|||

|

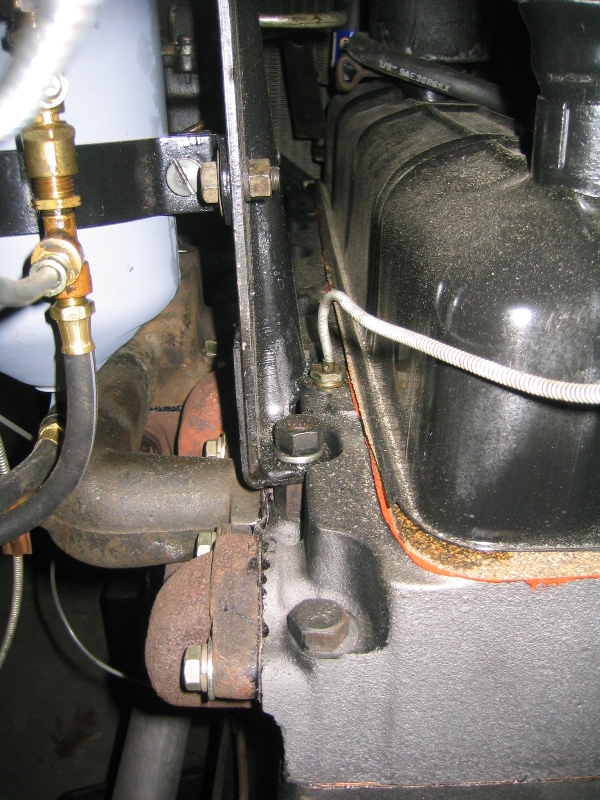

I'm now to the point in the reassembly of the HUP that the wiring harness, fuel lines, break lines have been all installed. One small weeper leak in the brake system of course it is the big fitting on the master cylinder which should seal OK just needs to be tightened but of course will mean bleeding the entire brake system again.

In painting small parts to reinstall I came across one brass marker light I'd heard that these existed but this is the first one that I actually seen. Cheers Phil

__________________

Phil Waterman `41 C60L Pattern 12 `42 C60S Radio Pattern 13 `45 HUP http://canadianmilitarypattern.com/ New e-mail Philip@canadianmilitarypattern.com |

|

| Thread Tools | |

| Display Modes | |

|

|