|

|

#61

|

|||

|

|||

|

Thanks David for the PM, Much appreciated

David... |

|

#62

|

||||

|

||||

|

Took the T-16 out over the weekend to attend a WWII military vehicle rally here in Texas. This allowed me to finally do some real test drives and check a few things out that couldn't be done in the front yard at home. Tracks are still loosening up and now the brakes have settled. So I'll need to adjust the control rods for all four of the tillers. The carb is still not performing as it should be so I was keeping the carrier in the lower gears so I'd have more power on the small hills and ditches. Should be able to resolve that one once I get a rebuild kit as I know I need to replace two of the parts.

Shot below is the carrier crossing a Bailey Bridge on the property.  Nothing fancy here but the kids had control of the camera all weekend and took photos mostly of the sky and our camp. They are used to seeing the Sherman, Hellcat and Stuart tanks each year so didn't take many shots of anything else.   This one shows the original GAU canvas meant to protect the wireless set. It has a weather flap rolled up on the top which is held that way with lift-the-dot fasteners. Almost all that I've seen are shrunk like this one and won't safely stretch over the armor wing. So I'm going to use mine as a pattern and see if one of the military canvas places can produce new reproductions which fit properly. If anyone else needs one for their T-16, post me a PM and we can see what the run will cost. More people means a cheaper price for everyone.   And if you have a high speed connection, this last link is a video clip of us driving over the bridge. http://www.youtube.com/watch?v=PQkUzSoUBVM

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#63

|

||||

|

||||

|

Great shots Dave, I never knew they dewalt flashlights back in the 40s

Colin. |

|

#64

|

||||

|

||||

|

Hey Mark, got your PM about the radio canvas and will call you tomorrow about the other things.

It's always been amazing to me Colin, how much junk people put into my vehicles at events and then forget. I've attended reenactments with my airborne jeep and almost always find rifles and webbing that people have dumped off to save carrying it. Then they go home and forget about it until they are packing for the next event and call to see if I might happen to have it. Turns out the torch was a friend's and he ended up camping near us the second day out there. Have some other shots from the weekend below. Mostly from the small public battle that was hosted on site. Me and the T-16 sat it out since it is pretty much a GI/German thing for the crowd. My older daughter got out there though with my full-auto Sten Mark V and her French Maquis impression.       Then there is my younger daugher wearing an original WWII Despatch Rider's pulp helmet. Who would have thought they made gear like that in such small sizes?  And of course the shot of her proving how hungry she is so I would start cooking the evening chow.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#65

|

||||

|

||||

|

I finally received approval from ATF after an almost five month wait so that I could convert an Enfield rifle into a smoke discharger action. Here in the USA it is considered a short barrel rifle so requires federal papers similar to a live machine gun or live artillery piece. They have to be careful since you never can tell when groups of gang members will dump their AK-47s in favor of cut down Enfieldís when they go on killing sprees

The rifle I used was very beaten down as it had a long service life. It started life as a 1908 Number I Mark III produced by LSA Co which was London Small Arms. In 1914 it was condemned to emergency use only and the barrel, receiver and butt stock had EY stampings added with the 1914 date also being added with those markings on the butt stock. It had the addition of wire wrappings to reinforce it as a grenade launcher but I don't know if that occurred later in WWI or during WWII. After cutting everything down and milling and threading the barrel for the 4" cup launcher and barrel nut, I blued the metal and refinished the wood which I'd carved down. Most of the carrier mounted launchers didn't retain the wood where the butt stock existed but I preferred to keep the wrist portion and carved it down into a small grip to make it easier to handle. Shots below show the launcher mounted in my T-16 with and without protective covers as well as some closer shots with it dismounted.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#66

|

|||

|

|||

|

On AFV applications its very eare to see the section of the butt left on.

The problem we have in the UK is that you cannot deactivate an idividual firearm component which is why you can't buy spare bren barrels to fit in your stowage. To be on the right side of the law the tube has to be permanently attached to the SMLE action which then makes it impossible to fit the discharger in some applications. I don't suppose you have a source for the covers? |

|

#67

|

||||

|

||||

|

Summerscales Army Surplus http://sas-surplus.co.uk/ has the canvas covers. Found them via eBay last year and I bought three covers in a fixed price listing. They were three for 5 GBPs at the time but now it looks like they are getting that much for each one. An example of their current eBay listings can be found at item number 360123135023.

I think these covers were for bore brushes. They are a Number 4 size which is roughly 4" diameter. I've seen Number 2 size covers coming out of Australia lately which people are selling under the guise of being 2-inch mortar muzzle covers. For the 4" smoke discharger, it takes two of the covers to build one which will fit since the inside diameter of the cup is 4". Essentially you need a bigger diameter end piece and about another 1.5" of side material to create a proper looking and fitting muzzle cover. The examples I received all had very closely matching canvas and all were 1943 dated. I made the new end disk from the donor cover where the markings were located so the final product seen on my launcher has nice markings on the side and on the end. Not sure what was really used during the war but would guess it was a shorter leather muzzle cover similar to the type used on 3-inch and 4.2-inch mortars. I've got examples of both of those for my mortars and they won't fit the smoke launcher barrel as one is too small and the other is too large.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#68

|

||||

|

||||

|

Finally have started work on the front and side fender skirts for the carrier. The originals were pretty mauled and rusted like most of the other panels I started out with. Slowly getting them hammered out so I can see if they will look right and then will repair cracks by welding and eventually strip and paint the parts.

First photo shows one of the side skirts with most of the dents beaten out and a front skirt that hangs below the curved fender with a lot more work needed.  Test fitting with longer bolts in reversed positions for easier and quicker panel mounting. Sure gets old having to bolt them up for fit, remove them for pounding and then repeat over and over since I don't have a better pattern to work from. Not a lot of fun but I guess it is still better than mowing the grass

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#69

|

||||

|

||||

|

Had the good fortune of picking up some floor drain plugs from another T-16 owner that had them made. Good news, bad news...

I'd been using pipe flanges since they exactly fit the recessed holes. And electrical conduit 1" caps would fit nicely into the flange to allow for it to serve as a functional drain in each location. I'd epoxy sealed them into the floor so they wouldn't bounce out prior to installing bins and fuel tanks since I never thought I'd find anything that would fit per the original design. Shot below shows how they looked from above on my pitted floor which isn't normally visible.  The problem I encountered is my own plugs were not intended for removal being installed from the inside. So now that I want to replace them, I had to remove the floor locker with battery and battery brackets, seat, seat bracket, locker that is mounted over the fuel tank, fuel tank itself after disconnecting the fuel lines, fuel tank holding box with brackets and the Bren gun spare barrel locker. All stacked up on my jeep and on the carrier.  So that I could spend 30 seconds screwing the proper plug into the floor from underneath as the designers intended. Last shot shows it in primer for reference prior to being painted and the joy of reinstalling all the removed parts.  At least its done properly now....

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#70

|

||||

|

||||

|

Decided to have copies of my fender skirts fabricated at our local sheet metal shop. I had managed to beat most of the dents and creases out of the driver side parts but the ones for the opposite side were significantly more pitted and abused. Figured if I needed to have one side rebuilt, might as well throw down and pay for the other side to match.

Shots showing test fitting with temporary bolts done backwards again to facilitate easier installation and removal.  Parts hanging in my Texas paint booth since the kids are at Grandma's house. Its been averaging 102-109F here for the past three weeks with no rain in sight. Only good thing to say for the dry heat is its good for painting. Little bugs that stick to the paint add texture and keeps with the consistency of my other outdoor painting.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#71

|

||||

|

||||

|

Got the painted fender skirts and mug guards installed and will take the carrier for a test run later today. That way I can see if it performs more aerodynamically

Since I was painting parts last week, I managed to fix my mangled gunner-side fender as well. Took a good bit of work even when straight to make it align with the mud guard and side skirt. Needed to use my floor jack with 4x4 pieces of lumber to coax it into playing nice but it seems to look OK now. Will probably require the floor jack to disassemble it should the need arise in the future.   Also built a part I've been missing from the start. Its the small mounting bracket for the pick head which bolts to the rear armor on the carriers. Forgot to take photos of building it so all I can post is a shot of it installed.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#72

|

||||

|

||||

|

David, I for one am going to be dissappointed when you have completed the carrier project and have nothing more to post up...

Thoroughly enjoyable ! Cheers Phill

__________________

Ford GPW Jeep USMC Ambulance Willys MB Jeep Daimler Ferret Mk 1 Daimler Ferret Mk 2 Land Rover S2A Field Workshop Land Rover S3 FItted For Radio x2 Land Rover Perentie GS (SASR) International No 1 Mk 3 2.5 Ton 4x4 International No 1 Mk 4 2.5 Ton 4x4 |

|

#73

|

||||

|

||||

|

Hey Phill,

As you know, they are never done since you can always find something to change out or upgrade. In my case, I'm now having to get the oil cooler that handles the engine oil repaired. I've had a small previously untraceable (to me) oil leak for about four months and knew it only occurred while driving. Idling in the garage never caused issues so I was thinking it was an oil pan gasket or hole in the pan near the block. Turns out it was a leak in the oil cooler on the back side and it was dribbling down the matrix and then running beneath a panel where it dripped under the radiator. Part of why it took so long to find as I only knew there was an oil leak somewhere underneath everything where I couldn't get a light. Already pulled and shipped off to a repair place here in the USA so hopefully it won't be costly. Certainly easier to fix than what I was dreading which was pulling the engine to look for a bigger issue. Shot shows the oil cooler with a small line I put on it to cap it off. That allowed me to place it in a bucket of water and put air inside to see if it bubbled for confirmation it was the culprit and not a line.  These are a few pictures I shot while ratting around and tearing up the land on the other side of my house that day in 107F heat.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#74

|

||||

|

||||

|

David,

I agree with Phil, but please keep this thread going for a little while longer as itīs so addictive! Why not make up an entire 4.2" mortar platoon, that should keep us going for the next few years  Thanks, Hanno

__________________

Regards, Hanno -------------------------- |

|

#75

|

||||

|

||||

|

yea dave get a entire platoon going.

all you need is 3 more carriers, and a support truck. dont know where you can fing that laying around do you???

__________________

44 GPW, 43 MB, 42 trailer, 43 cckw 44 MORRIS C8, M-3A1 SCOUT CAR 41 U/C, 42 U/C x 2, 44 U/C 42 6LB GUN and the list keeps growing, and growing.... i need help LOL |

|

#76

|

||||

|

||||

|

Give us some video!!!!

__________________

Model U.C. NO-2 MK II.* SERIAL 25680 HULL 24699. LOWER HULL 24742. ENGINE TL-26707-F. C.D. 2609. BUILT MAR. 25, 1944. CT 266677 Former WASP |

|

#77

|

||||

|

||||

|

have to say this is my favourite thread on MLU and a true testament to

"how it should be done" a utterly amazing rebuild and i only hope i can meet the quality of Daves build with my own. Richie

__________________

is mos redintegro __5th Div___46th Div__ 1942 Ford Universal Carrier No.3 MkI* Lower Hull No. 10131 War Department CT54508 (SOLD) 1944 Ford Universal Carrier MkII* (under restoration). 1944 Morris C8 radio body (under restoration). |

|

#78

|

||||

|

||||

|

Well I won't pretend to be ion the same league... but I hope that one day, in the (many) years to come, my little carrier may look something like this.

Thanks again for the inspiration Cheers Phill

__________________

Ford GPW Jeep USMC Ambulance Willys MB Jeep Daimler Ferret Mk 1 Daimler Ferret Mk 2 Land Rover S2A Field Workshop Land Rover S3 FItted For Radio x2 Land Rover Perentie GS (SASR) International No 1 Mk 3 2.5 Ton 4x4 International No 1 Mk 4 2.5 Ton 4x4 |

|

#79

|

||||

|

||||

|

Sorry, the only video of the carrier running since getting everything all together was shot a few months ago at Brent Mullins annual open house and vehicle rally. I'd posted it before but have it again here for reference.

http://www.youtube.com/watch?v=PQkUzSoUBVM We never seem to have a camera handy for shooting video when out doing test runs. Hopefully we'll get it hauled down to some ranch property in south Texas this fall when the weather cools down a bit and then can shoot video running in and out of the terraced fields and ditches. As for the mortar platoon arrangment, I'm working on it. I've gotton ATF approval for my 4.2" barrel to be live and functional and only need to make a firing pin stud to complete it now. Shooting 4.2" rounds will make for some really cool video

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#80

|

||||

|

||||

|

Below are some test shots I was doing for Nigel over the weekend before the oil cooler blew out. Wanted to see if high angle and overhead would prove to be neat effects since you don't see them too often and are always left simply seeing the flat hull walls on the carriers.

Not as cool as the little remote control carrier but it sort'a does look like a model from a distance when you can't see all the dirt on everything.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#81

|

||||

|

||||

|

Very nice.

__________________

Model U.C. NO-2 MK II.* SERIAL 25680 HULL 24699. LOWER HULL 24742. ENGINE TL-26707-F. C.D. 2609. BUILT MAR. 25, 1944. CT 266677 Former WASP |

|

#82

|

||||

|

||||

|

Not as cool as the little remote carrier

David Gordon!, have you been drinking or something?   This is the best carrier I have ever seen....EVER!, and as far as a little remote control toy; this leaves it for d,e,a,d - DEAD! I want to see a head-to-head with your T16 and a little remote controlled one. Sir I   to your work and ability. (So when do you think you'll be able to come down here and finish mine for me??) to your work and ability. (So when do you think you'll be able to come down here and finish mine for me??)I am very envious of your marvelous machine, and hope that one day mine is nearly as good. Pedr |

|

#83

|

||||

|

||||

|

Been awhile since I've been able to tinker with the T-16 due to other projects. Over the summer I'd had some issues with the engine seeming to flood while under a load. It would start, idle and rev fine but driving up hill in 95-105 degree heat once warmed up caused problems. The engine would choke down and applying more throttle in an attempt to increase power would have the opposite effect. Did some research and found things related to my issue on some of the rat-rod sites. Long story short it would appear my fuel pump was providing too much pressure for the carburetor and flooding it while running. Reasons could have included the length of the lift rod that operates the fuel pump, the lobes raising the lift rod, the thickness of the gaskets under the fuel pump and manifold, and the length/tension of the spring in the fuel pump. To compensate for too much pressure, you have to get into the carburetor which still wouldnít be a guarantee of anything.

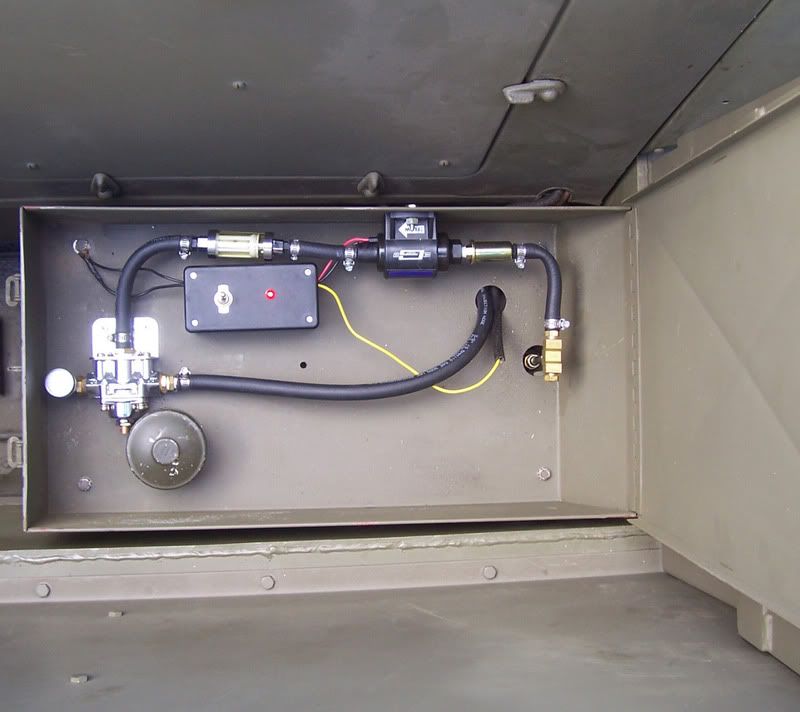

And for whatever reason, the factory WWII fuel pump delivers 4psi and the carburetor is designed for 3.5psi. Maybe not an issue with everything spot on but just one more concern when things arenít working as planned. After a lot of experimenting and testing different configurations, I decided to try some modern accessories. Figure I could always take them off. Plus I was looking for a solution to the heat saturation that can affect the fuel pump on Fordís where it is mounted high in a closed environment as on the T-16. So in an effort to keep things visually correct, I put all of the goodies inside the locker above one of the fuel tanks. Essentially ran rubber lines into the locker and up to an electric fuel pump. Added an in-line fuel filter which then leads to a Holley fuel pressure regulator set to 3.5psi. Then back out of the locker and connects back to my metal lines between the locker and fuel tank. From there it goes through the rest of the system as normal. I removed the lift rod from under the original fuel pump and the fuel simply is pushed up the lines and through it when everything is running. The little black box contains a fusible link and an idiot light along with a manual override switch. This way if the light is on, I know the fuse is good and power is on at the instrument panel. Flipping the switch will disable the electric fuel pump in the event that I need to crank the engine to clear it out and donít want fuel. So far everything works great. Ran the carrier up and down the street yesterday. Started off in 2nd and needed to shift to 3rd while accelerating uphill within a few feet. It now has the performance of a regular vehicle as it should. As it now stands, I may just leave it this way.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#84

|

||||

|

||||

|

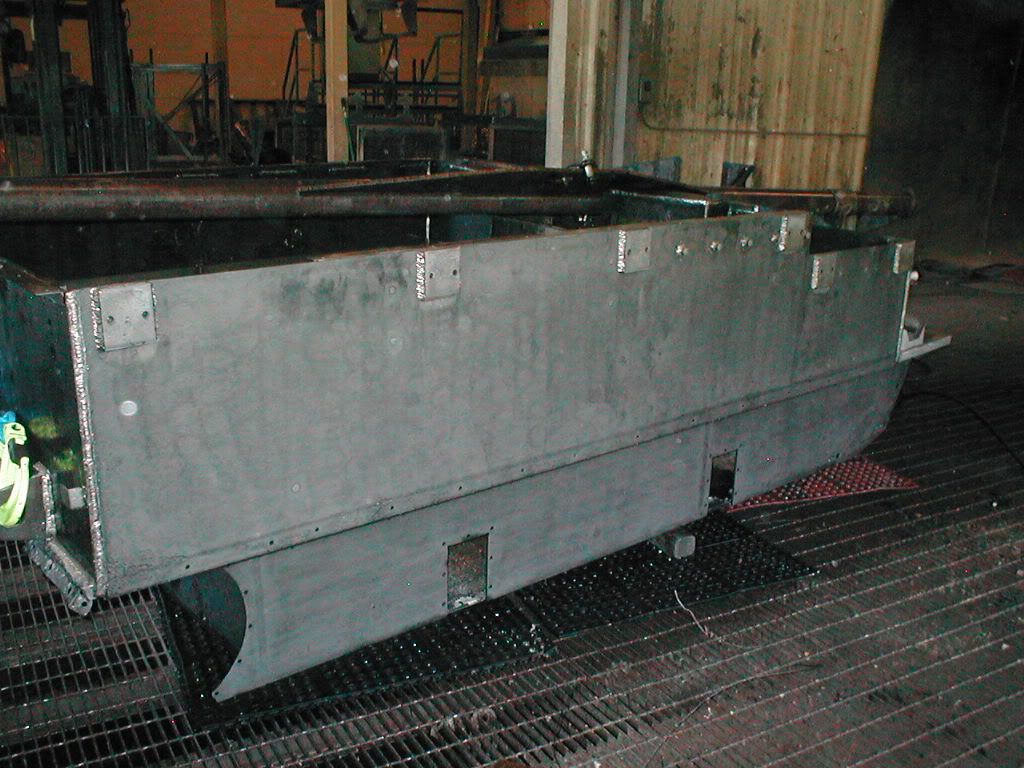

Since we're talking about rusty projects on a few other message threads, I figured I should post some of the shots showing how we chemically striped my carrier hull. All the welding work that is shown earlier in this message thread was completed before I had the hull dipped. Figure that was best with all the sheet metal I was replacing, holes to be welded up and then British wartime features being added back on. That way it could be primed after dipping and I wouldn't be grinding or burning paint off later on with new body work.

All of the armor is original and only light sheet metal areas inside the hull over the tracks was replaced with new metal. But old and new looks the same in the final shots. I also branded it "Tetanus" at that time due to the amount of rusty metal we had.     This next photo shows the hull about to go into the bath for the second time. First dip was killing the paint residue and pretreating the rust. It was then pressure washed before going in again.  Last two photos show the hull after the second bath but prior to being pressure washed off again. It was really shiny after it was washed but none of those photos came out.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#85

|

||||

|

||||

|

Blimey Dave! Is that facility in your back garden...not many of us have that

Also what are those chains coated with? That they come out still blue and yellow. Ron |

|

#86

|

||||

|

||||

|

I wish the place was in my back yard, but they are a 3.5 hour drive from where I live. I would have needed to trailer the hull to a sand blaster anyway so figured the extra drive time wouldn't make too much of a difference in the end. The real incentive is the facility made me a great deal. They had been dipping antique cars for years but had never done something heavy like the carrier. So it was a test for them to see if they wanted to start attracting military vehicle restoration people or not.

We were both really pleased with how the hull came out. And my cost was less than it would have been to sand blast since they made me a great deal for testing purposes. Numbers are all relevant to where you live and the time period we're talking about. Suffice to say they would now charge someone about three times what it would be for sand blasting. The process is a lot more thorough than sand blasting since it gets everywhere. And the chemicals won't eat good metal so there is nothing lost except for paint, grease and oxidation. Plus no sand residue falling out of all the little holes and channels on the vehicle. As for the chains, I'm not sure what they were coated with. I know that they were new since they were unsure of lifting the hull with what they had been using before at the shop. But the chemicals sure didn't touch them at all so likely it was a rubber coating of some type. They said the road wheels could safely be dipped since the rubber wouldn't be affected but I didn't want to risk testing them since it would have been expensive to replace them if they were wrong. Went the normal sand blasting route with all of my wheels.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#87

|

||||

|

||||

|

David,

A great restoration project. Do you have an idea of the weight of the hull in itself? I have excess to the same HC acid tanks through a family member, but he needs to know the weights... as they currently only strip classic cars and industrial paint machinary.

__________________

Alastair Lincoln, UK. Under Restoration: 1944 No2 MK2 Loyd Carrier - Tracked Towing 1944 Ford WOT6 Lorry The Loyd on Facebook |

|

#88

|

||||

|

||||

|

We added up other known item weights and worked backwards from what the total vehicle was supposed to weigh. Estimated the stripped hull at 3500 pounds. The gantry the dip place had was rated for two tons but they said it could probably hold a little more but didn't know it's true safety margin.

They didn't have a scale when it came time to testing things out but said it was easily within their normal weight limits based on having moved other vehicles around with their forklift and the gantry so I guess our initial estimates were pretty close. You'll notice in the shots that I took the bogie assembly mounting brackets off the lower hull. This was to further lighten it as well as to allow fast drainage of the chemicals due to their weight and added time it would have taken to lower and raise the hull if the liquid couldn't get in and out easier.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#89

|

||||

|

||||

|

Hello David and thanks for the pics. Chemically dipping large assemblies is of course the first choice of restoration techniques but even when I lived right in Sydney, near to a place that could do it (I was building jeeps back then) it was just too costly to have done. I wish I could afford to have the Scout hull dipped as even the sandblaster i hoped to have organised locally seems to have come to nought.

I am likely to have to carry my hull on a car trailer on a 600km round trip to Perth for sandblasting when the time comes...  Congratulations once again on a first class restoration by the way - simply awesome ! Cheers Phill

__________________

Ford GPW Jeep USMC Ambulance Willys MB Jeep Daimler Ferret Mk 1 Daimler Ferret Mk 2 Land Rover S2A Field Workshop Land Rover S3 FItted For Radio x2 Land Rover Perentie GS (SASR) International No 1 Mk 3 2.5 Ton 4x4 International No 1 Mk 4 2.5 Ton 4x4 |

|

#90

|

|||

|

|||

|

I would suggest a preliminary chemical treatment prior to the sand blasting.

The reason for this line of thought, is that mine has rusted badly in the floor, even though it was white blasted, cleaned, primed and painted, all on a fine dry day. I believe the armour plate forms large holes inside,from tiny pin holes at the surface, that the blasting process has no effect on.

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| my C15 restoration | rampant rivet | The Restoration Forum | 111 | 26-12-19 14:46 |

| M38 CDN Restoration | donjunior | Post-war Military Vehicles | 1 | 08-07-13 03:25 |

| 4.5 Restoration | James Shopland | The Gun Park | 7 | 18-03-13 17:38 |

| F8 for restoration | david moore | The Softskin Forum | 32 | 21-06-05 15:47 |

| Restoration tip........ | Bob Carriere | The Restoration Forum | 3 | 09-08-03 17:50 |